A BETTER WORLD THROUGH CHEMISTRY

In the factory city of Xiamen on China’s southeast coast, in the shadows of dramatic mountains, sits the plant of Xiamen Doingcom Chemical Company Ltd. The company is a key subsidiary of EcoGreen International Group Ltd.—a billion-dollar corporation listed on the Hong Kong stock exchange—and is one of the world’s leading suppliers of pine-derived flavor and fragrance chemicals. Into the plant come tanker trucks laden with distilled pine sap—gum turpentine—from the arboreal vastness of China. Out from the plant go container and tanker trucks filled with flavor and fragrance products. The most valuable of these products, revenue-wise, is dihydromyrcenol, a clean, citrusy fragrance used widely in soaps, shampoos, floor cleaners, even many big-name colognes.

The Xiamen Doingcom Chemical Company produces about 3,000 metric tons of dihydromyrcenol annually, supplying a large fraction of the world’s demand for the product. Why is it so successful in this market?

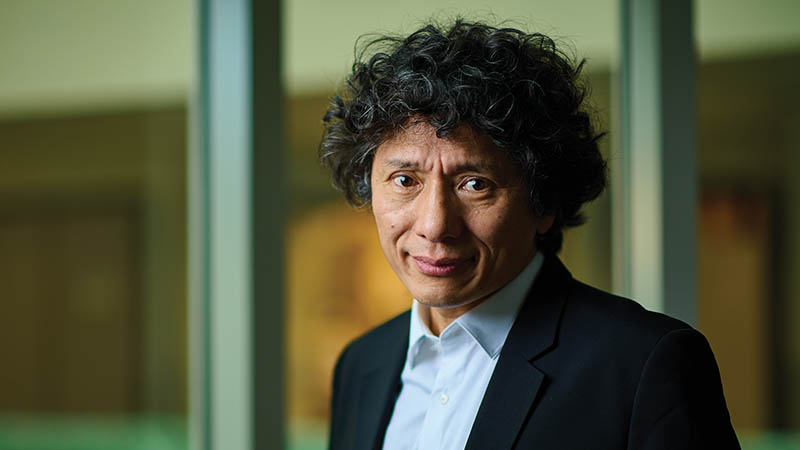

To a great extent, it’s because of Jin-Quan Yu.

Yu is now renowned for bigger feats and is the most-cited chemist in his field. But in 1990, as a 24-year-old research assistant at the Guangzhou Institute of Chemistry, he led the invention of a catalyst and reaction—still a trade secret—that enabled a strikingly more efficient and eco-friendly synthesis of dihydromyrcenol from its turpentine-derived precursor.

“In goes the cheap precursor chemical, and out comes gold,” Yu says with a laugh. “Change the catalyst once a month— that’s it.”

A BIGGER WORLD

Yu and a friend started a company to exploit the new dihydromyrcenol reaction—a company later bought by EcoGreen— and Yu reckons he’d be a billionaire by now if he’d continued working in that direction. But in 1994, he made the fateful choice to leave China to continue his studies abroad, a journey that eventually brought him to Scripps Research—and, in recent years, into the ranks of the world’s greatest chemists.

Yu’s fame among chemists stems from his development of methods for “C-H activation,” which essentially involves the cleaving of a bond that connects a hydrogen (H) atom to a carbon (C) atom on the backbone of an organic molecule, and the attaching of a larger cluster of atoms to the carbon. It’s a way of adding to the overall structure of the molecule, giving it properties—and usefulness—it didn’t have before. As an approach to molecule-building in organic synthetic chemistry, C-H activation always had a lot of potential, but, before Yu came along, it had a much more limited toolkit: The existing catalysts and methods for using them were often cumbersome and usually couldn’t be applied to a broad range of starting molecules. Yu’s work in C-H activation has yielded dozens of new catalysts and methods, many of them with unprecedented breadth of use—and virtually all of this work has been done at Scripps Research, which Yu joined in 2007.

Arenes and alkenes, phenols and enols, carboxylic acids and benzoic acids, amines and aldehydes—virtually every class of cheap chemical known to organic chemistry has been rendered amenable to C-H activation with catalysts invented by Yu and his team. The complex compounds one can make in these ways have been similarly diverse and potentially very valuable as pharmaceuticals or other chemical products. In goes the cheap precursor chemical, out comes gold.

“Yu’s work is changing the way that people discover and make new pharmaceuticals. He has invented techniques that are widely used in the pharmaceutical and other industries and not only are powerful, but also lead to greener, more efficient synthetic routes to key molecules,” says Stephen Buchwald, PhD, Camille Dreyfus Professor of Chemistry at the Massachusetts Institute of Technology.

OUTSIDE EVERY BOX

What were the original catalysts of Yu’s creativity and success? It’s a question that many are liable to ask, especially as his renown spreads—he’s won nearly all the big prizes, including a MacArthur Fellowship grant—beyond the recondite world of synthetic chemists. It’s essentially a mystery, and certainly not something one could ever mix in a flask. But one key factor seems to have been Yu’s extreme outsiderness, the wild-haired genius from nowhere.

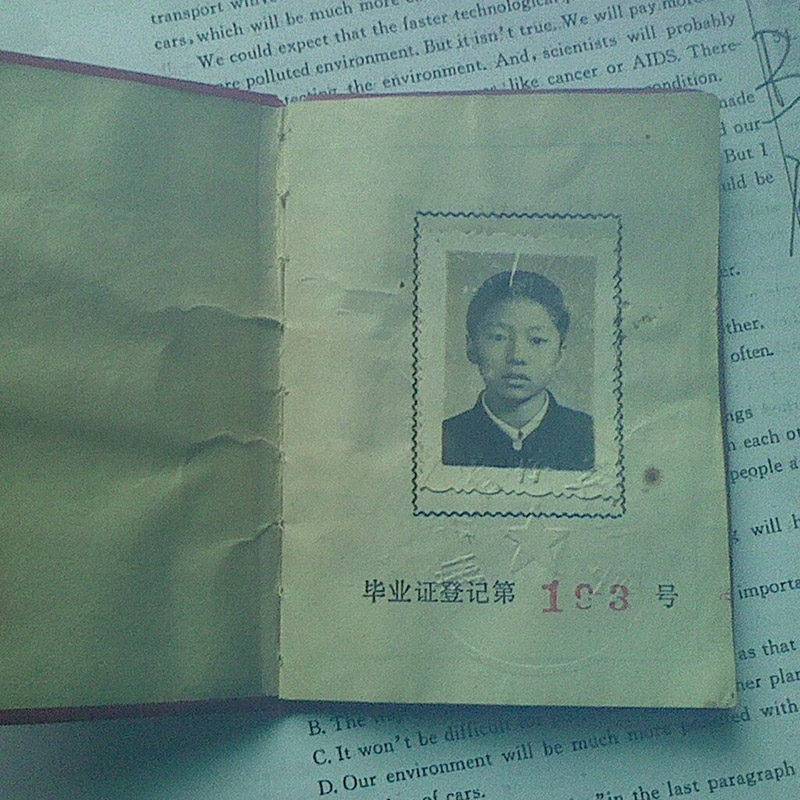

He was born in 1966, in a remote coal-mining valley on the western, mountainous side of Zhejiang province—China’s Appalachia, more or less. His father was a miner who suffered from a chronic mining-related lung ailment. Yu and his brother lived with their parents in an isolated cottage, the only one in their valley. The nearest village was miles away.

They lived without electricity and running water. To get water for the family, Yu and his brother daily would fill buckets from a nearby spring. Food came from a small garden they kept near the house, and from a modest share of crops grown on the local collective farm, also far away.

The family could not afford to buy salt, so Yu and his brother would walk ten miles to the coal mine where their father worked to gather empty burlap salt sacks from the mine’s small store. Bringing the sacks home, the boys would soak them in water, and then boil off the water to reveal precious crystals of sodium chloride. It was a more meaningful introduction to chemistry than most chemists have—and in general, that early, daily need to improvise, to make something from nothing, was probably another ingredient in his remarkable intellectual drive.

Elementary school, which Yu attended daily from the age of six, required a two-hour walk each way; the path went over a high, rocky hill and was interrupted by a river, which had to be crossed by a small ferryboat. The winter snows were deep. Yet Yu made the journey every school day, almost without fail. His parents sensed how exceptional he was, and pushed him to study, to be a good student, to learn his way to a better life. He dreamed of becoming a doctor so he could treat his father’s lung ailment.

At last, a bit of luck came his way. The Chinese Cultural Revolution, with its rejection of higher education, ended with the death of Mao Tse-tung in 1976, when Yu was 10. The new Chinese government began to encourage educational development, especially in the countryside, where it sent teams to remote villages to screen Chinese schoolchildren for exceptional talent. Yu, at the age of 13, was caught in this dragnet and sent to a special high school for gifted rural kids in a town 100 miles from his valley.

There, he saw his first bicycle and marveled at paved roads. And though considered something of a hayseed by the other students, he did well in school—he later would wonder if the simplicity and relative isolation of his early life had kept his mind freer and more fertile for the hard, multi-dimensional thinking that organic chemists have to do.

After three years of intense preparatory study, he scored high enough on China’s notoriously tough scholastic aptitude exam that he got into university. Unfortunately, medicine, his first choice for a major, was out of reach because he had never had a biology course.

He had to settle for chemistry.

IN A HURRY

Yu spent 12 years in higher education in China—first as an undergrad at East China Normal University, then as an M.S. student, research assistant and working chemist at the Guangzhou Institute of Chemistry—before heading to the U.K. in 1994 on a scholarship to do his doctorate at Cambridge. He was 28 by then, an age when most Western chemists already have their PhDs and are well into their careers. The late start left him with the feeling that he needed to move quickly.

“There was always a sense of urgency associated with every interaction with him, as if he always had to get back to the fume hood because there was something going on,” says his close friend and fellow Scripps Research chemist Phil Baran, PhD, who met Yu in 2001 when they were both doing postdoctoral work at Harvard.

Yu’s organic chemistry work in Guangzhou, supervised by his mentor Shude Xiao, PhD, had been concerned largely with syntheses of natural compounds found in pine trees. Understandably, then, when he went abroad for further training, he planned to learn more about how “biosynthesis” in plants and animals—mediated mostly by enzymes— occurs.

Enzymes are usually exquisitely adapted by evolution to catalyze specific biochemical reactions. But as molecule-building tools they aren’t very flexible—they are hard to adapt for making new things. In part for that reason, Yu was soon drawn to organic synthetic chemistry, often seen as the intellectual core of modern chemistry. Its practitioners devise step-by-step reactions to build molecules flexibly, never using cells or enzymes. At Harvard he studied under E.J. Corey, PhD, a Nobel laureate widely regarded as the godfather of the organic synthesis field. But the shift from biosynthetic chemistry had left Yu feeling even further behind.

“It was pretty intimidating when I went to the Corey lab,” recalls Yu, holder of the Bristol Myers Squibb Endowed Chair in Chemistry. “Some in the group viewed me almost as like a kindergartner, because of my lack of experience in organic synthesis. But Professor Corey was extremely patient and thoughtful in teaching me.”

Yu reasoned that because he had missed the training and experience his colleagues had, there was little point in trying to catch up to do the kinds of things they were doing. Instead, he would have to blaze his own trail. With help and encouragement from Corey, he began to re-orient his thinking in an important new direction.

“Jin-Quan Yu has solved some of the most challenging problems in the metal-catalyzed carbon-hydrogen (C-H) bond activation area. His work has had an immense impact in both academics and industry, which has made him a leader in this field of research.”

-Robert Bergman, PhD, The Gerald E.K. Branch Distinguished Professor of Chemistry, Emeritus, at the University of California, Berkeley

DISTANCE AND GEOMETRY

Then, as now, organic synthetic chemists who wanted to build a new and valuable molecule often sought starting compounds whose backbones contain double bonds— typically between two carbon atoms, or a carbon and an oxygen. Why? Because chemists had a reasonably good set of tools for using these double bonds as handles for adding modifications. Yu’s dihydromyrcenol synthesis, for example, had involved the design of a catalyst that could crack one of the double bonds in the precursor molecule to add a hydroxyl (-OH), while avoiding the other double bond.

Yu decided instead to focus his synthetic efforts on a different type of bond, the carbon-hydrogen (C-H) single bond. Carbon atoms in organic molecules are usually festooned with hydrogen atoms via C-H bonds. But when he was starting out, Yu found there were relatively few good and versatile catalysts for using C-H bonds as handles for molecule-building. A big part of the problem was that chemists didn’t have a lot of tools for cracking one of these bonds on a molecule without affecting the others.

Yu, however, had a sense that he could design catalysts for selective C-H bond- cracking—and if they could be used to build many different classes of compound, with efficient and eco-friendly reactions . . . well, he could just about revolutionize synthetic chemistry by making the construction of diverse, useful molecules easier than ever. That in a nutshell is what Yu’s career in organic synthesis has been about.

Most of his methods have employed, within the all-important catalyst molecule or complex, an atom of the precious metal palladium, an atomic-scale wrecking ball that is particularly good at cracking C-H bonds. The challenge is that the wrecking ball has to be positioned precisely to crack only the targeted C-H bond—and Yu’s catalysts are designed to do just that, anchoring themselves to the starting molecule with a precise geometry to ensure that the wrecking ball will selectively hit just one C-H bond.

“Traditionally, organic chemists have relied heavily on the electrical charge-related properties of molecules to control reactivity and selectivity in reactions, based on fundamental principles of physics,” Yu says. “To me, this approach never seemed very useful for targeting C-H bonds, because, in electronics terms, the differences between these bonds in starting compounds is usually negligible.”

Yu refers to his more structural-mechanical approach as “distance and geometry,” and sees this reconceptualization not only as a key to making C-H activations work, but also as a new paradigm that will drive advances generally in the field of synthetic chemistry.

CHIRALITY AND SCALE

Some of the knock-on advances from Yu’s innovations have been happening in his own lab, and in themselves represent big innovations.

One is the new ease of enantioselective synthesis. Enantiomeric, or chiral, molecules are those whose asymmetry allows them to be made in “left-handed” or “right-handed” forms—which have the same chemical formula and may be products of the same reaction, though they are often functionally distinct. Trying to find easy routes to selectively make one enantiomer of a compound but not the other has been a major theme in modern organic synthesis, especially in pharmaceutical chemistry. By moving away from the traditional emphasis on double-bond chemistry and using their own versatile tools for selective C-H activations of simple starting compounds, Yu and his team have started to make enantioselective synthesis almost routine.

These and other molecule-building innovations from Yu’s lab have, by now, been widely adopted by chemists in the pharmaceutical industry.

“His methodologies are broadly applicable to the medicinal chemistry community while being practical and straightforward to implement—hallmarks of his approach—and have had an immense impact on the practice of molecule assembly and molecular editing,” says Nicholas Meanwell, PhD, executive director of discovery chemistry at Bristol Myers Squibb, which has been collaborating with the Yu lab since 2012.

Another big advance, which Yu sees as a potential capstone to his career, connects back to his youthful feat of turning pine sap into liquid gold at industrial scale. The key to success then was an efficient, scalable and eco-friendly hydroxylation of the precursor compound. The method was ingenious enough to disrupt that niche industry, but it was conventional in the sense that it targeted a C-C double bond. Now Yu and his group are using their breakthrough C-H activation tools to do hydroxylations—an often-challenging step in molecule-building at scale—with an unprecedented diversity of choices in terms of starting compounds and final products. And, once again, they are finding eco-friendly ways to do this: for example, by using cheap hydrogen peroxide (yielding water as a side product), or even O2 gas as the oxygen source, and without having to consume energy by heating the reaction.

“These are breakthroughs that will impact not only discovery chemistry, where you’re making a few grams of the product for initial tests in drug discovery, but also the ton-scale chemistry of bulk chemical manufacturing,” Yu says. “In fact, that’s my big dream now, to see these reactions used for large-scale production of medicines and other chemical compounds that the world needs.”